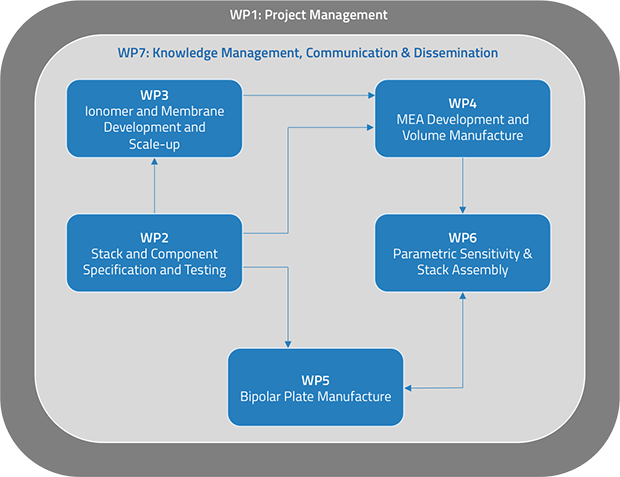

Figure: Overall technical work flow for the project showing linkage between work packages Figure: Overall technical work flow for the project showing linkage between work packages |

The VOLUMETRIQ project is composed of 5 technical work packages (WP2 – WP6) and 2 supporting workpackages (WP1 & WP7) dedicated to project management and knowledge dissemination . Within the technical work packages, membrane electrode assemblies (MEAs) with improved power density and manufacturability will be generated through work package 3 for ionomer, reinforcement and membrane, feeding into work package 4 for catalyst coated membrane (CCM) and gas diffusion layer (GDL), whilst under work package 5 the performance and manufacturability of the bipolar plate will be optimised. Work package 6 will feed into work packages 4 and 5 delivering information about the sensitivity of fuel cell performance to the various component properties enabling manufacturing quality to be enhanced. |

Work Package Description

This workpackage is where the primary controlling management is undertaken ensuring the work proceeds on time and to budget and that activities are effectively co-ordinated between work packages.

In this work package the fuel cell stack requirements will be defined with these then cascaded down to component level. Individual components specifications will target low cost mass manufacture although the primary cost reduction measure will be achieved by improving the operational current density Cost reduction measures and projections will be compared against the FCH-JU Multi – Annual Work Programme 2014 – 2020

The membrane electrode assembly (MEA) sub-components that will be used (reinforcement, ionomer, catalyst) have already been developed to TRL5 prior to the commencement of this project. The focus of VOLUMETRIQ will be the industrial scalability of these materials and the application of appropriate production processes

The main objective is for JMFC to demonstrate the manufacturing capability of high performance sealed catalyst coated membrane (CCM). Accelerated durability, stress test, full ex-situ characterisation and post mortem tests will be used to ensure the CCM meets the automotive requirements.

The key focus for EK will be on demonstrating capability and repeatability of the bipolar plate production process moving from blank sheet material format to using high volume compatible roll feed arrangements.

The key objectives of this work package are to achieve the cell performance targets, to ensure component quality and consistency, to develop high volume production processes for the components, and build and test a fuel cell stack using the production intent components.

This workpackage involves all the partners and includes three tasks concerning:

|

Pellentesque adipiscing leo condimentum enim ullamcorper pretium. Aenean gravida, libero nec convallis ornare, massa odio.

Pellentesque adipiscing leo condimentum enim ullamcorper pretium. Aenean gravida, libero nec convallis ornare, massa odio.